katup kontrol pneumatik cryogenic

katup kontrol pneumatik cryogenic

Spesifikasi teknis

2.1 Lembar Tanggal

| Katup kontrol kriogenik pneumatik Tipe awak: | langsung liwat casting jinis globe |

| Tipe plug katup: | non-balanced single seat plug type |

| Ukuran nominal: | DN20~200,、NPS 3/4〞~ 8〞 |

| Tekanan nominal: | PN16 ~ 100、KELAS 150LB ~ 600LB |

| Koneksi: flange: | FF、RF、MF、RTJ |

| Welding: | SW、BW |

| Ukuran Flange: | Miturut IEC 60534 |

| Katup pengatur kriogenik pneumatik Tipe bonnet: | Ⅲ: Tipe ditambahi suhu kurang(-196℃~ 45℃) |

| Packing: | V tipe PFTE packing, fleksibel.packing grafit, lsp. |

| Gasket: | Kemasan logam grafit |

| Katup pengatur kriogenik pneumatikAktuator: | Pneumatik: aktuator diafragma multi-spring, aktuator tipe piston. |

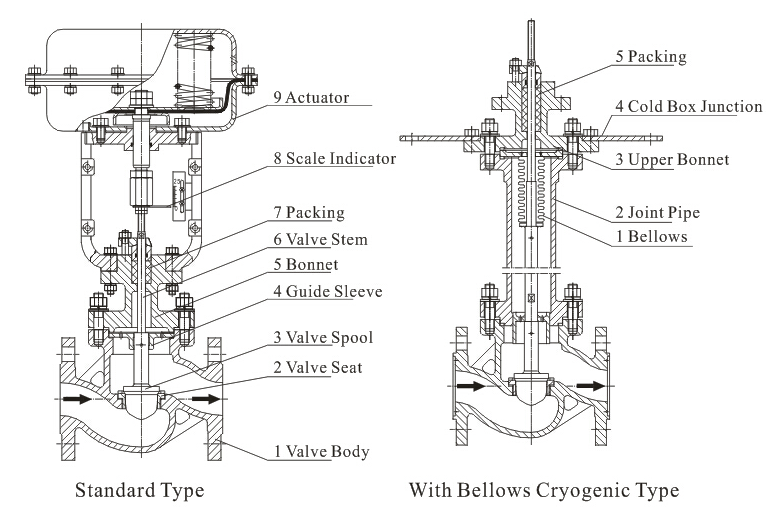

2.2 Gambar struktur katup kontrol cryogenic

2.3 Daftar bahan katup kontrol cryogenic

| Jeneng komponen | Bahan Katup Kontrol |

| Badan/Bonet | LCB/LCC/LF2/CF8/CF8M/CF3M |

| Katup spool / Kursi | 304/316/316L (overlaying stellite alloy) |

| Packing | Normal: -196~150℃yaiku PTFE |

| Gasket | Normal: Baja tahan karat kanthi grafit fleksibel, Khusus: paking jenis gigi logam |

| Tutup Diafragma | Normal: Q235, Khusus: 304 |

| Diafragma | NBR kanthi kain poliester sing dikuatake |

| Spring | Normal: 60Si2Mn, Khusus: 50CrVa |

| Kontrol katup stem | 2Cr13/17-4PH/304/316/316L |

2.4Low bahan suhu cocog dhaftar suhu

| Casting | Forging | ||

| Bahan | Kerja paling murah suhu | Bahan | Kerja paling murah suhu |

| LCB | -46°C | LF2 | -46°C |

| LCC | -46°C | -46°C | |

| LC1 | -59°C | LF5 | -59°C |

| LC2 | -73°C | LF9 | -73°C |

| LC3 | -101°C | LF3 | -101°C |

| CF8 | -254°C | F304 | -254°C |

| CF8M | -254°C | F316 | -254°C |

| CF3 | -254°C | F304L | -254°C |

| CF3M | -254°C | F316L | -254°C |

2.5 kinerja katup kontrol cryogenic

| Katup pengatur kriogenik pneumatik Karakteristik aliran | Linear, persentase, mbukak cepet |

| Kisaran sing diidini | 50: 1 (CV<6.3 30: 1) |

| Nilai Cv sing dirating | Persentase CV1.6~630,linear CV1.8~690 |

| Katup pengatur kriogenik pneumatik Kebocoran sing diidini | Seal logam: kelas IV(0,01% kapasitas dirating) Segel alus: kelas VI(kelas busa) Standar bocor: GB / T 4213 |

| Pneumatic cryogenic ngatur katup Performance | |

| % kesalahan intrinsik | ± 1.5 |

| Beda bali,% | ≤1.5 |

| Zona mati,% | ≤0.6 |

| Bedane saka wiwitan nganti pungkasan,% | ± 2.5 |

| Rated travel prabédan,% | ≤2.5 |

2.6 Parameter aktuator katup kontrol cryogenic

| Tipe Katup Kontrol\ Metode | Aktuator diafragma pneumatik |

| PZMA-4~PZMA-7 | |

| Tipe multi-spring | |

| Panganggone | Tipe ngatur, jinis ON-OFF |

| Tekanan pasokan udara utawa voltase sumber daya | Tekanan suplai udara (Spring range) 140(20~100)Kpa G 240 (40~200) Kpa G 280 (80~240) Kpa G |

| Konektor | Konektor pipa udara: RC1/4 |

| Tindakan langsung | Tambah tekanan, batang mudhun, tutup tutup. |

| Reaksi | Tambah tekanan, stem munggah, katup mbukak. |

| Sinyal input | 40~20mA.DC(karo positioner) |

| Lag | ≤1%FS(karo positioner) |

| Tipe linear | 2% FS(karo positioner) |

| Suhu lingkungan | -10℃~+70℃ |

| Katup pengatur kriogenik pneumatik Aksesoris | E/P, P/P valve positioner, filter regulator, valve converter, solenoid valve, switch winates Aksesori non-standar, butuh cathetan khusus sing disesuaikan. |

2.7 Parameter teknis katup kontrol cryogenic

| Diameter kursi (mm) | 10 | 12 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |

| Dirating Cv | Persentase | 1.6 | 2.5 | 4.0 | 6.3 | 10 | 16 | 25 | 40 | 63 | 100 | 160 | 250 | 400 | 630 |

| Linear | 1.8 | 2.8 | 4.4 | 6.9 | 11 | 17.6 | 27.5 | 44 | 69 | 110 | 176 | 275 | 440 | 690 | |

| Nom.ukuran | Dolan | Karakteristik aliran pilihan Cv.(★standar ●dianjurake ○dikustomisasi) | |||||||||||||

| DN20 | 16 mm | ● | ● | ● | ★ | ||||||||||

| DN25 | ● | ● | ● | ● | ★ | ||||||||||

| DN32 | 25 mm | ○ | ○ | ○ | ○ | ○ | ★ | ||||||||

| DN40 | ○ | ○ | ○ | ○ | ● | ★ | |||||||||

| DN50 | ○ | ○ | ○ | ● | ● | ★ | |||||||||

| DN65 | 40 mm | ○ | ○ | ○ | ★ | ||||||||||

| DN80 | ○ | ○ | ○ | ● | ★ | ||||||||||

| DN100 | ○ | ○ | ○ | ● | ● | ★ | |||||||||

| DN125 | 60 mm | ○ | ○ | ○ | ★ | ||||||||||

| DN150 | ○ | ○ | ● | ★ | |||||||||||

| DN200 | ○ | ○ | ● | ● | ★ | ||||||||||

| Aktuator pneumatik Area diafragma, Ae(cm2) | PZMA-4 | PZMA-5 | PZMA-6 | PZMA-7 | |||||||||||

| 280 | 400 | 600 | 1000 | ||||||||||||

| Tumindak | Range spring | Katup pengatur kriogenik pneumatik Metal sealing allowable pressure difference (MPa) | |||||||||||||

| Hawa mbukak | 20-100KPa | 4.46 | 3.09 | 1.98 | 1.16 | 0.7 | 0.44 | 0.28 | 0.18 | 0.17 | 0.11 | 0.07 | 0.07 | 0.05 | 0.03 |

| 40-200 KPa | 6.4 | 6.4 | 5.94 | 3.34 | 2.14 | 1.31 | 0.84 | 0.53 | 0.51 | 0.33 | 0.21 | 0.22 | 0.15 | 0.09 | |

| 80-240 KPa | 6.4 | 6.4 | 6.4 | 6.4 | 4.99 | 3.05 | 1.95 | 1.25 | 1.18 | 0.78 | 0.5 | 0.51 | 0.36 | 0.21 | |

| Udhara nutup | 20-100KPa | 6.4 | 6.19 | 3.96 | 2.23 | 2.14 | 0.87 | 0.56 | 0.35 | 0.34 | 0.22 | 0.14 | 0.15 | 0.1 | 0.06 |

| 40-200 KPa | 6.4 | 6.4 | 6.4 | 6.4 | 6.4 | 5.86 | 3.64 | 2.3 | 2.21 | 1.43 | 0.91 | 0.95 | 0.66 | 0.37 | |

| 80-240 KPa | 6.4 | 6.4 | 6.4 | 6.4 | 6.4 | 6.4 | 5.04 | 3.18 | 3.06 | 1.98 | 1.26 | 1.32 | 0.92 | 0.52 | |

Tulis pesen ing kene lan kirimake menyang kita